Transition Bath’s treasurer Hugh Prentice has been running a sustainable mushroom farm in the vaults under the old railway station at Green Park in Bath since March 2014. He has been collecting coffee grounds from cafes and restaurants on a daily basis and using the grounds to grow mushrooms which he then sells at the Saturday Farmers Market which is immediately above.

In July his mushroom yields dropped significantly because temperatures in the vaults had risen to 27C, significantly above the recommended 15C optimum growing conditions for mushrooms. He asked Transition Bath’s Energy Group, a local energy consultant Piers Sadler and others for advice and recommendations on how he could better manage temperatures and environmental conditions in the vaults. He has now implemented most of the recommendations and combined with lower ambient temperatures his farm is now back in full production.

The main recommendations were to partition the vaults up into different climatic zones which Hugh has now done. Ongoing research is taking place including the use of thermal imaging, temperature logging, blue LEDs and switching to more heat tolerant mushrooms in order to sustainably ensure high yields throughout the year.

An outline of the ongoing research and background information on the mushroom farm is provided below or in this pdf.

Ongoing research to make Fungi Fruit’s Mushroom Farm at Green Park Station more sustainable

Summary

There are a number of areas of research taking placing at Fungi Fruit’s mushroom farm in the vaults under the old railway station at Green Park in Bath. Their aim is to improve yield and to make the farm more sustainable. The research includes:

- The use of blue LEDs to reduce electricity consumption and heat produced by the lighting

- Thermal imaging of the incubation and fruiting stages to try to understand the biological processes better

- Temperature and CO2 logging to understand how to better manage and optimise temperatures and CO2 levels in the vaults

- Reorganisation of the vaults, including partitioning to better manage temperatures and airflow

- Some research into sterilisation to reduce the growth of green mould

The research was prompted by a period of high temperatures in the vaults in July 2014 which significantly reduced yields. This report provides background information on the mushroom farm, why the research is taking place and what progress has been made to date. The research is on-going, final results will probably not be complete for 2 years – following 2 full summers to see if the proposed solutions from the research work.

Background to research/advice/recommendations

Hugh Prentice has been successfully running his crowd-funded mushroom farm ‘Fungi Fruits’ since March in the vaults under Green Park Station. In July he started running into problems with reduced yield as a result of high summer temperatures and asked a number of experts to help him solve these problems:

- Transition Bath’s Energy Group, Piers Sadler, an Energy Consultant from Bristol who provided an environmental audit and recommendations

- Adrian Ogden of Gourmet Mushrooms, a mushroom expert who provided advice on mushroom varieties and growing conditions based on 15 years of experience

- Paul Petty an electronics expert who has been researching blue LEDs

It is hoped the resultant advice and research will lead to improved yields, particularly during periods of high ambient temperatures and make the farm more sustainable. It is also hoped that the results of this research will help others starting similar businesses. .

Background: Fungi Fruits/Bath Mushroom

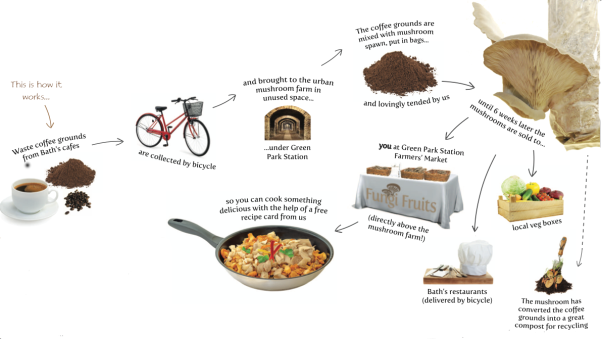

Hugh started his business in March 2014 from the vaults under the old Green Park Station in Bath. The process involves collecting 50 kg of used coffee grounds from cafes and restaurants in the centre of Bath using a hand cart on a daily basis. The grounds are then mixed with bought-in oyster mushroom spawn and left to incubate in warm ‘summer’ conditions for 3 weeks, before being moved to cooler “autumnal” conditions to fruit. The mushrooms are then harvested and sold to local restaurants and via a stand at Saturday’s Green Park Farmers Market immediately above the vaults. A diagram from Hugh’s website explains the process well:

Environmental Requirements

Mushroom cultivation is quite sensitive to environmental conditions. The growing phase of the process is split into 2:

- Incubation: After the coffee grounds are mixed with the spore they are ideally left at 20C in bags for 3 weeks to incubate in the dark. The 20C simulates summer conditions:

2. Fruiting: Following incubation the bags are hung up and left to Fruit. At this stage temperatures are reduced to 15C to simulate Autumn and they are lit to 1000-2000 LUX for 8 hours per day using fluorescent lamps:

During this stage the mushrooms produce a lot of CO2 which needs to be removed to encourage growth. Ideally CO2 concentrations need to be kept below 900 ppm; this is typically achieved using fans providing a high rate of ventilation of perhaps 6 air changes per hour. After about 2 weeks the mushrooms fruit out of the sides of the bags and are ready to be harvested:

.

Why did mushroom production slowdown in July?

Prior to July mushroom production had been reasonable without Hugh needing to actively manage the temperature, CO2 and green mould. But in July as outside temperature rose, combined with the heat produced by the fluorescent lamps and the mushroom growth, temperatures within the vaults rose to 27C almost completely halting mushroom growth and causing Hugh to stop selling his mushrooms at the market.

Hugh was facing 3 challenges:

- it was too hot in the vaults for the mushrooms to fruit

- there wasn’t enough air flow to dissipate the CO2

- naturally occurring green mould was outcompeting the mushroom at the higher temperatures

Green Mould

Green mould is a naturally occurring pathogen whose optimum growing conditions are nearly identical to those of mushrooms, and is a serious cause of reduced yields in modern mushroom production. In commercial farms a sterilised substrate is often used to reduce the chances of green mould out-competing the mushrooms. For Hugh this is more difficult as he relies on collecting used coffee grounds from a variety of cafes and restaurants in Bath. The process of making the cup of coffee – passing near-boiling water through the coffee – partially pasturises the coffee, but never completely sterilises it.

Hugh has therefore considered a number of strategies:

- Optimising mushroom growing conditions: optimising the conditions so mushrooms outcompete green mould; these include getting the right temperatures, and not diluting the concentrations of mushroom spawn in the substrate too much

- Managing coffee ground sources carefully: Hugh has built up relationships with most suppliers of the coffee grounds, so that the staff in the coffee shops have modified some of their processes to help eliminate contaminants in the coffee grounds. Once it has been collected, all coffee mixed with mushroom spawn and bagged is tracked. No coffee shop has provided consistently un-contaminated coffee, but it has been noticed that some cafés’ used coffee grounds seem to produce more green mould than others. Hugh hopes through careful documentation and separation to better understand why some sources seem to have higher levels of green mould than others: it is unclear at the moment whether the problem is caused by the source coffee beans (are natural beans worse than more processed beans?) or how the waste grounds are managed in individual cafes.

- Sterilisation: this is commonly used in commercial mushroom farms to decontaminate the substrate. Hugh would like to avoid this as it is both energy intensive (i.e. not sustainable) and labour intensive. He would like to focus on the other techniques described above first.

Incubation bags of mushrooms contaminated by green mould

Solution 1: Improving the environmental conditions

In August Piers Sadler was invited to visit the vaults, assess the situation and provide recommendations. Thermal Imaging and temperature logging were subsequently carried out. In addition mushroom expert Adrian Ogden from Leeds visited to provide further advice.

Airflow and Temperature Control

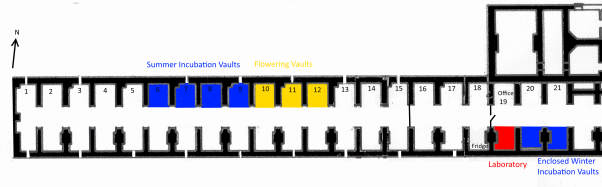

The most obvious challenge in the vaults was how to manage the temperature. In its original layout the incubation phase was located in bay 20, where heating was required to bring the temperature up to 20C. During July temperatures here had risen so much that the incubating bags were temporarily moved to the cooler bays 6 to 9, while a longer term solution was found. During July the temperature in the Fruiting bays had also risen, along with the CO2 levels. In August the layout was:

The 27C temperatures reached in the vaults in July were caused by a combination of:

- heat generated by the biological processes in the incubation phase

- heat from the 2.5 kW of fluorescent lightings required 8 hours per day in the fruiting stage

- external ambient air temperatures

- lack of air circulation/ventilation

Even the considerable thermal mass of the vaults appears to have only limited impact in reducing these temperatures.

In resolving the problems, the following solutions were proposed:

- separate the incubation and fruiting phases

- locate the incubation phase nearer the warmer end of the vaults, to benefit from the heat from the main part of the building in winter, but with access to ventilation shafts to help with cooling in the summer

- fan driven night purging of the vaults with cooler ambient air

- create a buffer zone between the two zones, both to allow a temperature gradient and to allow for access to ventilation shafts – ventilation both to help control temperature, but also to provide oxygen to the fruiting phase

- locate the fruiting phase towards the west end of the vaults – leaving bays to the west for ventilation. Bay 1 also has some solar gain in the summer – and this is to be avoided.

It was therefore proposed that the vaults be split into zones by installing partitioning across the vaults:

The fruiting stage would be enclosed with partitions at each end and fans installed to ensure adequate airflow, drawing oxygen in through ventilation shafts and from the buffer zone, and expelling CO2 westwards through the ventilation shafts in bays 1 and 3.

This arrangement would allow different environmental zones for the incubation and fruiting stages and in future support a variety of environmental controls for each zone.

Progress

As of October 2014 Hugh has completed most of this work, installing insulated partitions around each zone and hydroponic fans to improve airflow and reduce CO2 concentrations:

Rigid Celotex insulation has been used to insulate the incubation zone, and separate it from winter conditions below 20C in the adjacent buffer zone. The temperature in the incubation phase has been managed by spacing the bags – grouping them closer as the ambient temperature has fallen below 20C – the heat generated from the growth in the bags has maintained the temperature in the bay. The reverse will apply in the summer – when additional cooling will be required.

Hydroponic fans have been installed in the fruiting bays, and this ventilation has reduced the CO2 levels to below 900 ppm. Evaporative cooling was applied in August and September, but with falling external temperatures, this has not been continued.

Yields are now significantly improved and Hugh is selling his mushrooms again at Green Park Farmers Market.

Solution 2: Use of blue LEDs

Hugh initially installed 2.5 kW of fluorescent lighting, but research is now taking place to see if this can be made more efficient by switching to blue LEDs. Although LED lighting and modern fluorescent lighting have similar efficiencies (~90 lumens/watt) research suggests that much of the red and green end of the spectrum is not used by mushrooms during their fruiting stage. By switching to blue LEDs electricity consumption could reduce by 50% – this not only saves electricity costs but potentially will reduce the heat generated by the lighting and the need for expensive air conditioning next summer.

The photos below show Hugh’s original fluorescent setup and the new experimental blue LED setup:

This research is being carried out by Paul Petty.

Solution 3: Using different types of oyster mushrooms in summer

Hugh is currently growing a European winter variety of oyster mushroom which the reference manuals recommend fruiting in temperatures between 10C and 15C, but recent experience tells us that they will fruit in temperatures up to 18C if other conditions are suitable. Different varieties of oyster mushrooms are also grown in South East Asia in much hotter conditions, up to 30C; these are being considered for use during the summer in the vaults as it will reduce the need for active cooling making the vaults more sustainable and cheaper to run. This is the ethos of the project – planning to grow the mushrooms suitable to the conditions, rather than trying to manipulate the conditions to grow the better known mushrooms.

Research: Thermal Imaging

Because Transition Bath’s thermal imaging camera was available to the project it was decided to try using it to see if it would help provide further insight into the temperature control issues in the vaults.

The initial results of the thermographic survey which took place in August and October included:

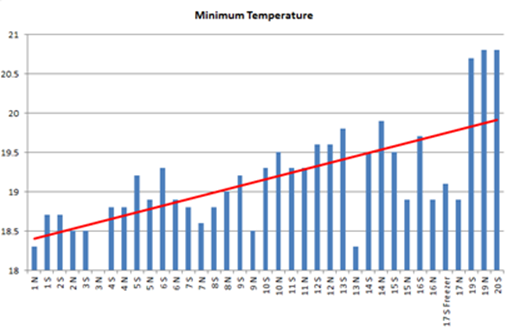

- There were no specific hot spots in temperature within the structure of the vaults and very little temperature contrast. There was a slight temperature gradient of about 1.5C rising from west to east:

This appears to be largely caused by heat generated from the fluorescent lighting (in bays 10 to 12) and incubation phase, originally in bay 20. (the horizontal scale is numbered vaults 1 to 20) Bays 19 and 20 are within the main building of the station, and are warmer because of this.

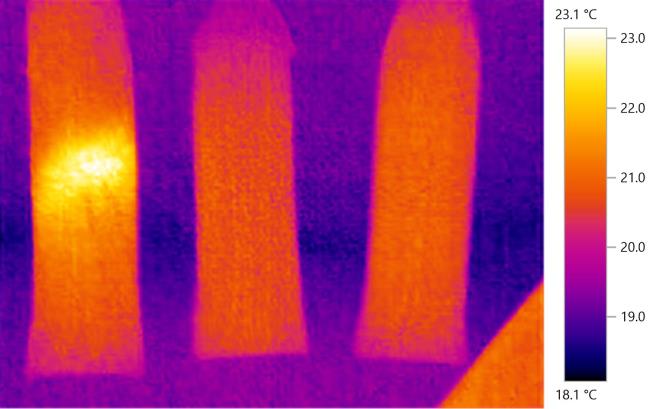

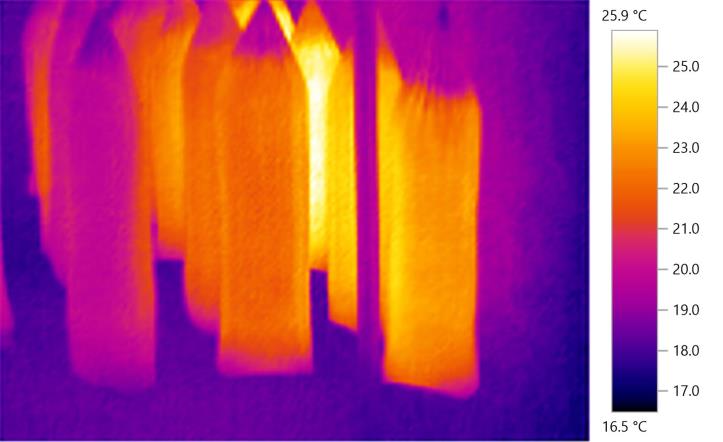

- It appears it might be possible to detect green mould by the additional heat it generates before it is visible to the eye:

This has the potential to more proactively manage the green mould before it infects whole bags – more research needed. (centre section of left hand bag is hotter and has green mould)

2. Significant heat is generated during the incubation phase but not the fruiting stage. After initial incubation the heat in the bags gradually rises over a period of a few days and then reduces after a week or two:

The ‘newest’ bags (6 days old) are on the right of this image, the oldest on the left (14 days old). There is a 6C temperature difference between the bags. There is a potential to improve the efficiency of the farm by reducing the period bags are in incubation from 3 weeks to 2 weeks by better monitoring of temperatures – once a bag reaches a lower temperature it might be an indication the incubation period is over and the bag could be moved to the fruiting stage? Further research will take place by installing temperature logging equipment in example bags to better understand the biological processes and temperature changes of the incubation phase.

Additionally, with a better understanding of the heat generated by the growth in the bag, and the rate of heat generation over time, it will be possible to improve the temperature control of the whole space, without having to implement other energy-intensive heating/cooling methods. Options to consider are using different spacings between the bags – eg closer in winter; and interspersing older bags with newer ones to avoid buildup of heat in some areas of the bay.

Research: Temperature logging

10 of Transition Bath’s temperature loggers have been installed throughout the vaults to better understand how temperatures vary both during the day and over longer periods of time. The data has been compared with the external temperatures recorded by Paul WiIman’s weather station in Bath. This will help to better understand future heating and cooling requirements and for example potentially to predict in summer when a switch to a more heat tolerant variety of oyster mushroom is required or whether active cooling might be need to be turned on.

The initial findings of this research include:

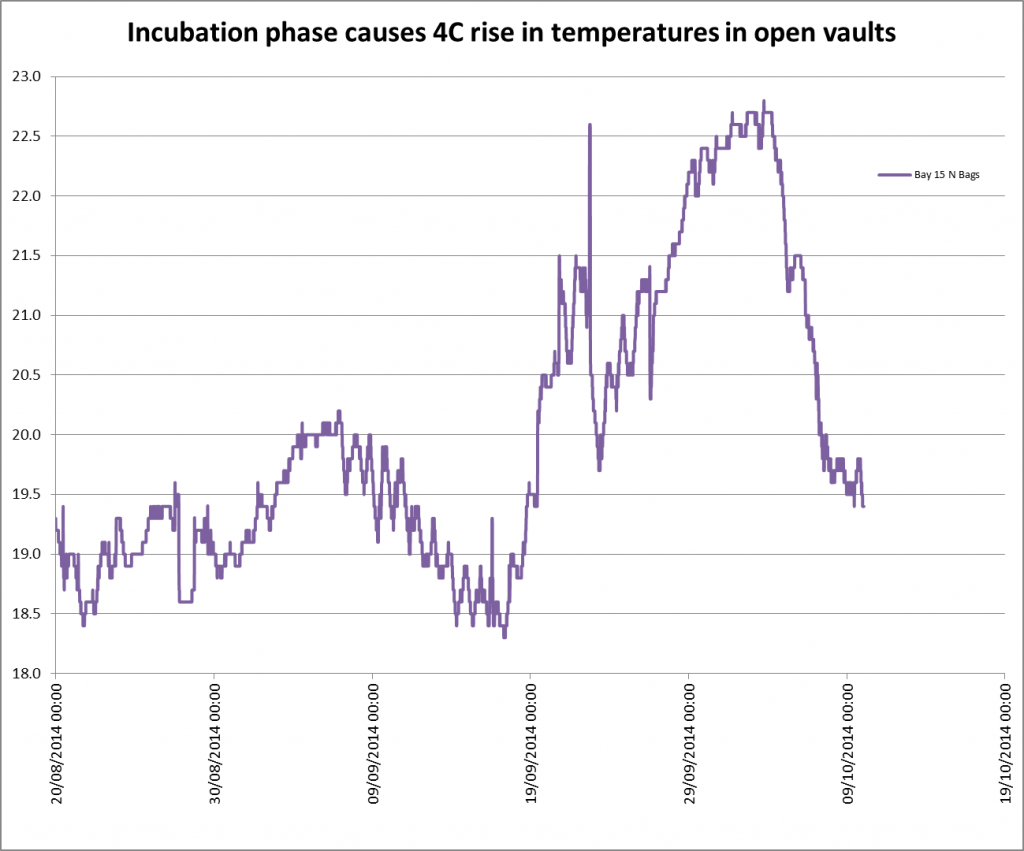

1. The incubation phase, even in an open vault generates a lot of heat:

This graph shows the temperature in one vault over a 6 week period. The temperature rises significantly once incubation is started (18 Sep 2014)

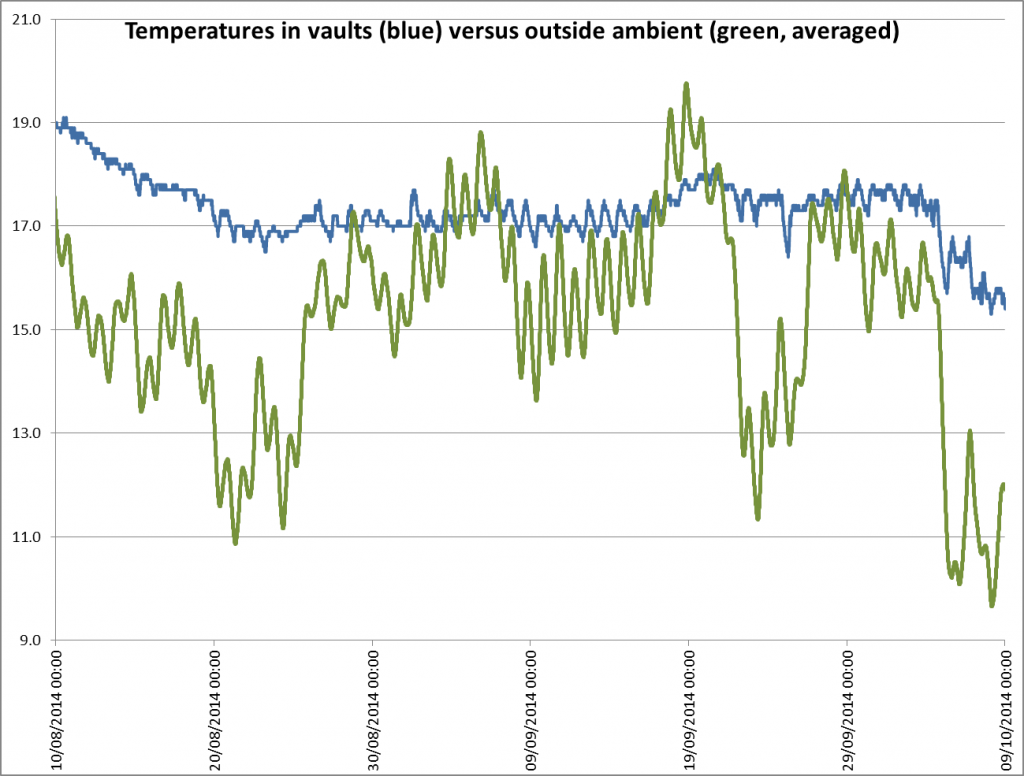

2. Ambient temperatures have some impact on the vaults:

Recent drops in outside temperatures have affected the vaults, but the thermal mass of the brickwork, and the heat generated by the farm have dampened down the impact.

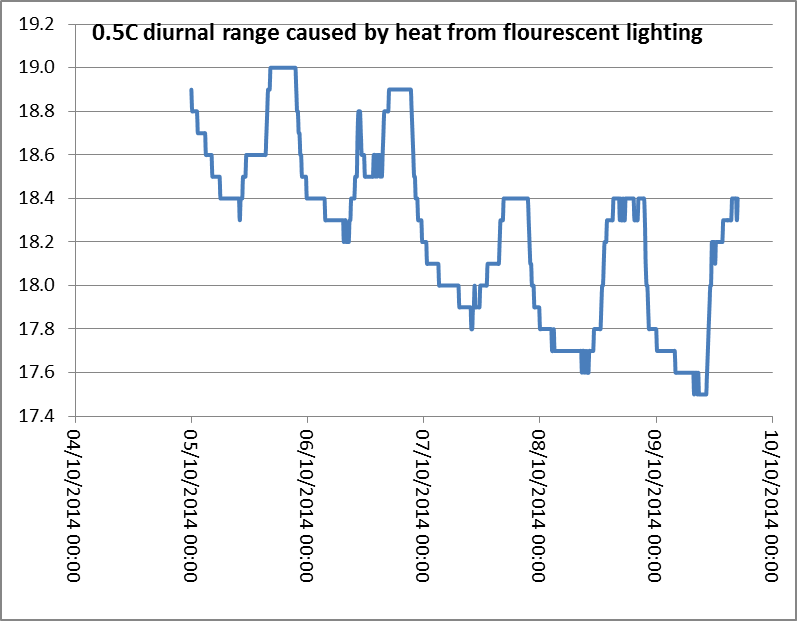

3. The heat generated by the fluorescent lighting running 8 hours per day during the fruiting stage has a diurnal impact of about 0.6C which was much less than expected:

This change in temperatures caused by the heat from the2.5 kW of fluorescent lighting is less than expected and requires further monitoring especially once the partitioning work and fan installations have been completed on the vaults and also if the blue LED lighting is moved from a research to a production stage. This and a combination of the thermographic imaging of the fruiting stage do however suggest the internal heat gain in the vaults from the fruiting stage might be less that was initially anticipated.

Research: CO2 monitoring

Hugh has recently purchased a CO2 monitor to try to optimise airflow in the vaults. Mushroom growing produces a significant amount of CO2, but high concentrations of CO2 also inhibit mushroom growth. At the fruiting stage, industry standard recommendations are to keep CO2 concentrations below 900 ppm which equates to a relatively high 6 air changes per hour. Hydroponic fans have recently been installed in the vaults to increase air flows and CO2 levels will be monitored Increasing the airflow has a potential downside in that more active heating and cooling may be required as it increases the potential for outside ambient temperatures to have a greater negative influence on temperatures in the vaults. Mechanical Ventilation and Heat Recovery (MVHR) systems have been considered to better manage the relationship between temperatures and air flow but at the moment they have been discounted because of the challenges of filtering the often spore laden air before it reaches the MVHR units air conditioners.

Further research and monitoring is required in this area.

Conclusions

Mushroom yields have already increased significantly since August and Hugh is now back again selling mushrooms at Green Park Farmers Market, he is also increasing the amounts of coffee being collected in anticipation that the problems we had in the summer are now over and production can get back to ‘normal’ and be scaled up

Hugh’s previous experience and this research has led to the development of methods of controlling temperature that do not rely on using additional energy to heat/cool, but rather to adapt to conditions and work within them. The partitioning of the vaults following recommendations from Piers Sadler’s environmental survey will provide greater control, allowing the incubation stage to be maintained closer to its 20C optimal temperature and the fruiting stage to its 15C. Ongoing research into blue LEDs and through temperature logging should help reduce the mushroom farms electricity consumption and manage the temperatures in the vaults more consistently leading to high yields. We would also hope through night air purging, evaporative cooling and switching to other varieties of oyster mushrooms during the summer will avoid the problems the farm suffered this summer in future years.

Background Reading

- Fungi Fruits website

- 2011 BBC article on Mushroom Farming in caves near Bradford on Avon, plus 1963 Pathé News video

- Brief article on this project on Piers Sadler’s website

- Article on Transition Bath’s website about Hugh’s mushroom farm

- “Integrated Environmental Control in Mushroom Tunnels”, James Grant, Liam Staunton, Kinsealy Research Centre, 1999

- “An Investigation Of The Airflow In Mushroom Growing Structures, The Development Of Improved, Three-Dimensional Solution Technique For Fluid Flow And Its Evaluation For The Modelling Of Mushroom Growing Structures”, James Grant, Dublin City University, 2002, Phd Thesis, pp326